Flow Transmitter

Vedika Instruments is one of the leading Flow Transmitter Manufacturers in Uttar Pradesh. It accurately measures the flow rate of any conducting liquid or slurry that is flowing in closed pipes. It is obstruction-less and hence offers no pressure drop in the process. The absence of moving parts ensures that there is no need for maintenance. The performance of the instrument is not affected by the properties of the material such as corrosiveness, viscosity, density, acidity and alkalinity. It can measure the flow of liquids, pastes and slurries in water, and wastewater. Suitable for chemical, fertilizer, paper, dairy, sugar, food and beverage industries.

Measurement Techniques

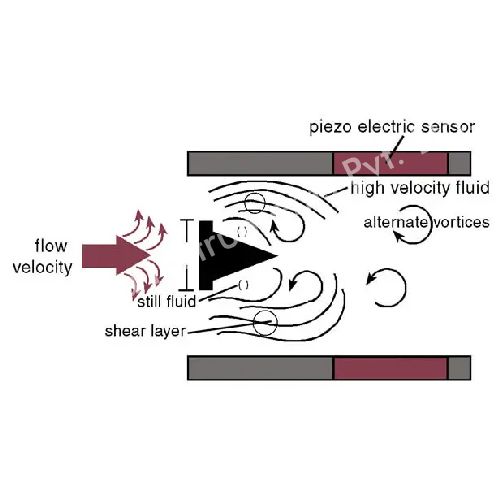

Flow transmitters use positive displacement (PD), true mass flow, ultrasonic, electromagnetic and other measurement techniques.

- PD devices divide liquids into specific increments that are counted by mechanical or electronic methods. Examples of PD meters include piston meters, oval gear meters, nutating discs, and rotameters.

- True mass flow meters measure the rate of flow in terms of mass and include devices such as thermal meters and Coriolis meters.

- Ultrasonic meters include both Doppler-effect meters and time-of-flight meters.

- Electromagnetic devices use the liquid as the conductor and a magnetic field is created by energized coils outside a flow tube.

- Elbow meters operate on the principle that when liquid travels in a circular path, centrifugal force is exerted along the outer edges.

Specifications and Features

Flow transmitters vary in terms of operating conditions, flow range parameters, performance measurements, and optional features. Operating conditions include maximum operating pressure, fluid temperature range, and operating temperature.

Measured in pounds per square inch (psi), operating pressure is the maximum head pressure that flow transmitters can withstand.

Fluid temperature range, a function of construction and liner materials, is usually measured in degrees Fahrenheit; however, metric devices are commonly available. Flow range parameters for flow transmitters include velocity flow rate range, volumetric flow rate range, and mass flow rate range.

- Mass flow rate is the range of flow in mass/time. The specification applies to mass flow sensors and meters.

- Velocity flow rate range is the range of flow in distance/time. This specification applies to velocity flow sensors and meters.

- Gas volumetric flow rate range is the range of flow in volume/time. This specification applies to volumetric flow sensors and meters for gases.

Output Options

Flow transmitters output analog voltages, analog currents, frequencies and pulses.

Analog voltage outputs are simple, usually linear, functions of the measurement. They are continuous rather than pulsed or discrete.

Analog current outputs are suitable for sending signals over long distances. They include current loops such as 4 – 20 mA and use feedback to provide an appropriate current regardless of impedance or noise.

Frequency and pulse signal outputs are encoded via amplitude modulation (AM), frequency modulation (FM), and pulse width modulation (PWM). They are also expressed as sine waves and pulse trains. Some flow transmitters are inserted perpendicular to the flow path and require a threaded-hole pipe for access. Others are inserted parallel to the flow patch between two pieces of process pipes and clamped into place.

Suitable For:-

- Chemicals

- Pharmaceutical industries

- Petrochemical industries

- Refineries

- Oil and fuel tanks etc.