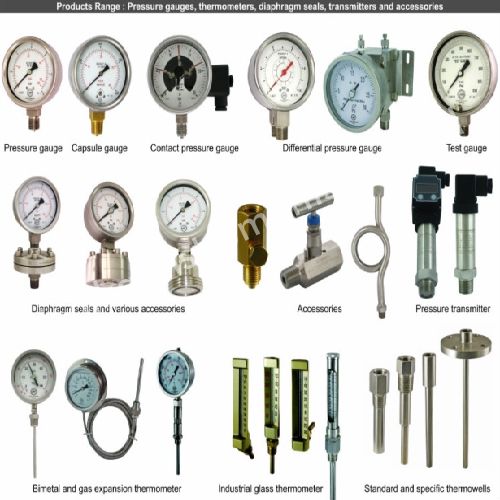

Temperature Gauge

Vedika Instruments Pvt. Ltd. is known as one of the leading Temperature Gauge Manufacturers in Uttar Pradesh.

Bi-Metallic Temperature Gauge

The Temperature is measured with a bimetal system inside the thermometer stem. The bimetal system consists of two metal strips bounded together that have different thermal expansion coefficients. Therefore, one strip will expand faster than the other causing the bimetal strip to curl in proportionate temperature. The bimetal system is helically wound and heat treated for long term stability. Temperature variations cause the bimetal strip to unwind or wind together, which in turn rotates the pointer.

Gas Filled Temperature Gauge

A Gas Expansion Thermometer is made of a cylindrical bulb filled with inert gases & uses the volume expansion of gases at temperature changes. Gas Pressure changes inside the bulb due to temperature changes are sensed by a special helical bourdon tube, which is connected to an amplifying device will give the pointer movement proportional to the temperature. The physical properties used will enable linear reading on the dial from the original to the full scale. When the reading is remote from the sensing point, a capillary is then used for transmission between the bulb and the thermometer head. Capillary armoring is common practice in industrial environments.

Mercury Filled Temperature Gauge

A Mercury Filled Thermometer is made of a cylindrical bulb filled with mercury & uses the volume expansion of gases at temperature changes. Mercury with Gas Pressure changes inside the bulb due to temperature changes are sensed by a special helical bourdon tube, which is connected to an amplifying device will give the pointer movement proportional to the temperature. The physical properties used will enable linear reading on the dial from the original to the full scale. When the reading is remote from the sensing point, a capillary is then used for transmission between the bulb and the thermometer head. Capillary armoring is common practice in industrial environments.

Technical Specification

- Reference Standard:- ASME 840.200(840.J Grade A)/ IS13211/ EN13190/ IEC-60529

- Sensing Element:- Bimetallic Helix (Coiled type)

- Dial Size:- 63/ 100/ 150/ 250 mm.

- Scale Range : -80°C ~ +650°C (as per customer requirement)

- Mounting: Bottom/ Back/ Every Angle Entry

- Process Connection : 1/8”, ¼”, ½”, ¾”, 1” BSP or NPT Thread

- Connection: Adjustable or Fixed welded connection

- Stem Dia : 6/ 8/ 10/ 12 mm.

- Stem Length: as per customer requirement

- Gauge Accuracy : +/- 1% F.S

- Over range Protection: 130% F.S.D

- Case & Bezel : SS304/ SS316

- Stem: SS316

- Protection Window: Plain Glass/ Toughened Glass/ Safety Glass

- Pointer: Aluminum

- Zero reset: Zero adjustment pointer (internal)

- Dial: Aluminum (Black marking on white background)

- Protection Class : Whether proof IP65/ IP67/ IP68 (as per IP standard IP-60529)